Industrial Robots Remote Monitoring

The stability and reliability of robots in the production line are of great significance to the economic benefits of production. Equipped with edge computing capabilities, the IG902 pre-processes, filters and cleans the constantly streaming data before sending them to the cloud, relieving the pressure of the data center and enhancing efficiency.

Background

With the global wave of industrial IoT, modern industrial robots have been widely used in flexible manufacturing. The stability and reliability of robots in the production line are of great significance to the economic benefits of production. The complex structures and high maintenance costs place great demands on the maintenance capabilities of technicians, who are expected to detect faults in the structure and control devices, remind users of maintenance before the machine shuts down.

Faced with the current status of robot application, and to meet the requirement of higher service quality from industrial robot device manufacturers, InHand offers the InGateway902 edge computing gateway, assisting manufacturers in devising a complete remote monitoring and management solution for industrial robots.

Solution

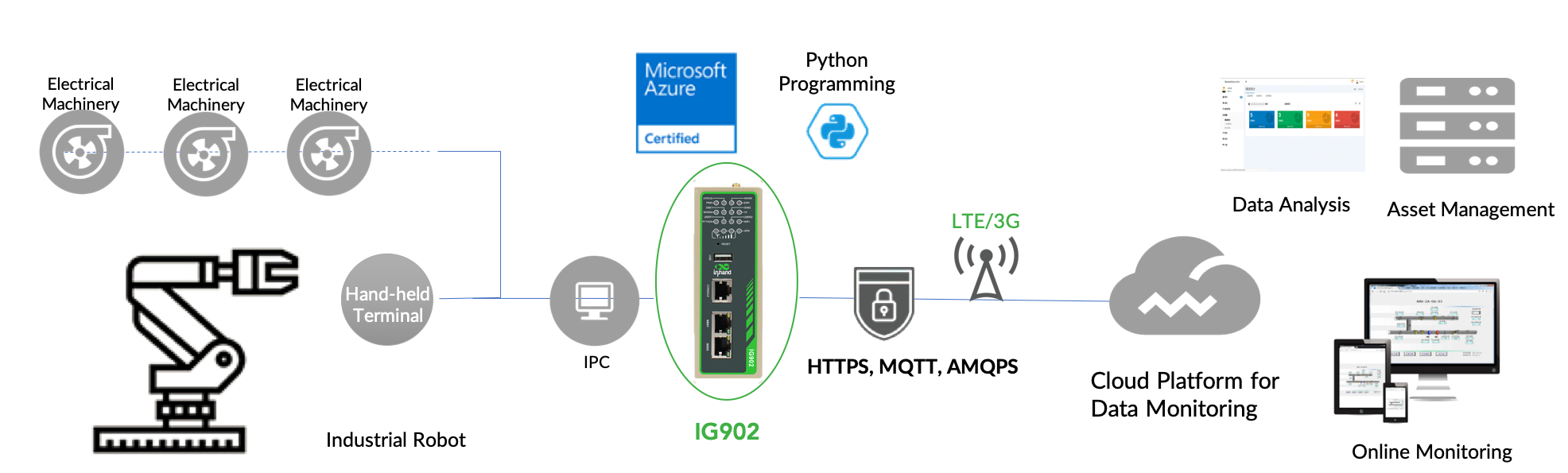

The industrial robot on the production site consists of the robot, the hand-held terminal and the control system. Via high-speed Ethernet, the core control system is connected to the IG902 which collects data of the robot's operation status, such as the axis set velocity, axis feedback velocity, axis accelerated velocity, axis feedback location, axis alarm code, temperature of the electrical machinery, shaft torque, etc.

The IG902 can pre-process, filter and clean the collected data. The processed data is then sent to the cloud platform via frequently used IoT protocols such as MQTT and HTTP. The cloud platform can be deployed at the enterprise's private data center or Microsoft Azure cloud service platform. The platform can remotely monitor the status of devices, conduct preventive maintenance and mine industrial big data.

Why InGateway902?

- Enables data pre-processing, filtering, cleaning and data security protection

- 4G LTE cellular access

- Supports Microsoft Azure and AWS Greengrass cloud access

- Python-based development environment

- Supports VLAN function

- Receive commands from cloud and inform field devices

- Support secure maintenance tunnels for remote debug and firmware upgrade

- All industrial design, EMC grade 3