Concrete Mixing Equipment Remote Monitoring Solution

The technical performance of concrete mixing equipment is crucial to the quality of construction projects. The IR915 4G industrial router offers reliable wireless communications to the system, enables remote maintenance, diagnostics and early warning, reducing equipment downtime and enhancing the efficiency of manufacturers.

Background

The technical performance of concrete mixing equipment of batch plants can directly affect the quality and service life of the construction projects. Concrete batch plants need to perform routine maintenance to timely detect, maintain and repair any defective parts of the mixing equipment, to reduce damage and prevent equipment from being unable to perform normal production operations. The fault elimination and maintenance of concrete mixing equipment were traditionally done by local service departments of the manufacturer, or by manufacturer employees sent to the site. This will not only bring after-sales service costs high, but will also affect the production progress of the batch plants.

Intelligentization is the ultimate development direction of mechanical equipment, the concrete mixing equipment is no exception. InHand introduces a remote maintenance system for concrete mixing equipment based on PLC and wireless communication technology, using InHand 4G industrial router IR915. The maintenance staff can perform remote diagnosis, early warning and maintenance of the mixing equipment in real time while away from the production site.

InHand Reomte Monitoring Solution

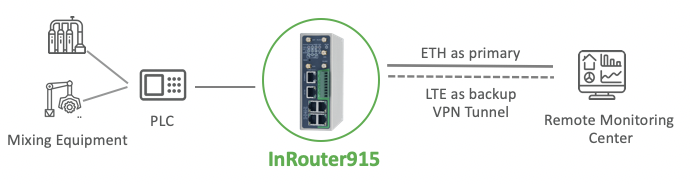

The monitoring system of concrete mixing equipment consists PLC, edge computing gateway InRouter915 and cloud monitoring center.

- The InHand edge computing gateway InRouter915 connects one or more field PLCs to form a field network of concrete mixing equipment, collect data of field controllers and sensors, and upload the data intelligently with local caching mechanism.

- The edge computing gateway runs a data acquisition APP within and transmit the APP data to the cloud monitoring center through MQTT protocols. In this way, data reliability, real-time and security are ensured, and data flow costs is saved.

- The field data is uploaded to the cloud monitoring center, maintenance staff can remotely diagnose, pre-alert and maintain the mixing equipment in real time away from the production site, and can monitor a large number of concrete mixing stations.

Advantages

InRouter900 gateway:

- IR900 industrial smart gateway supports dual link backup and VRRP technology, providing link redundancy when the main link fails

- CE, FCC, UL, PTCRB, CCC, Verizon Wireless, AT&T certified, applicable globally

- Fully industrial grade, providing reliable, secure and stable data transmission links for unattended sites

- Through Python programming, can develop edge computing capability for data analysis and processing, customer can customize the intelligent logic processing, local pre-processing

- Built-in GPS module, positioning more accurately comparing with base station data

- Microsoft Azure IoT certified