Remote Monitoring of Injection Molding Machines

Featuring strong data transmission and edge computing capabilities, the IG502 offers a remote monitoring solution for distributed machines and enhances efficiency for facility operation and maintenance.

Background

Traditional injection molding machines are controlled by local switches. This implies that alerts may not be responded immediately, and that maintenance can only be done through manual patrol, which is rather time- and labor-consuming. In the era of Industry 4.0 where everything is supposed to be ?smart?, it is required that distributed equipment in the factory be constantly monitored and managed from a central location, so that operation and maintenance costs can be cut through prompt response to faults and preventive maintenance.Remote Monitoring Solution of Injection Molding Machines

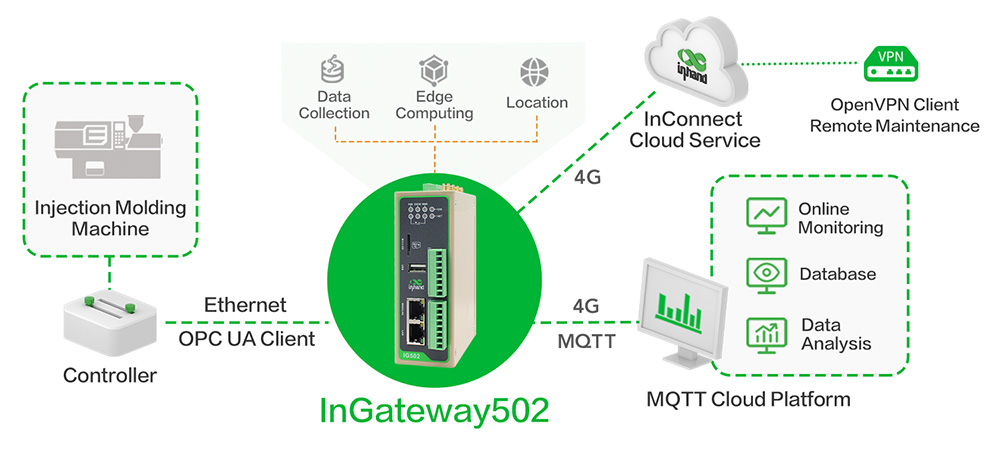

Onsite injection molding machines are connected to the IG502 via Ethernet ports. The IG502 collects data from the machine controller which is using OPC UA Client and then uploads the data to the customer?s MQTT server. Meanwhile, with the InConnect offering a tunnel for remote maintenance, engineers can update or modify the programs for the controller via OpenVPN. The IG502 supports local web view of real-time data, cache of breakpoint data, so that operation status can be viewed anytime as long as the machines are connected to the Internet.

Why IG502?

- Industrial design, sustaining and faultless operation ensured;

- Python programmable, the IG502 enables users to custom logic processing, so that data can be treated locally, thus relieving the workload on the cloud;

- Supports resuming of breakpoint data, 8GB eMMC FLASH, Micro SD supported;

- Multiple industrial protocols supported, such as Modbus TCP/RTU, OPC UA Client, etc.;

- Complete ?cloud + edge? solution shortens the period for debugging and enhances efficiency;

- Data transmitted to the cloud via MQTT protocol, which is easier for use compared to traditional VPN.