Remote Monitoring for Oil Wells

Oil wells feature a lot of unmanned devices are geographically spaced out. In this case, having PLCs and terminal devices with HMI systems connected to InRouter600 via Ethernet, and having InConnect service empowered enable remote maintenance, online PLC programs uploading or downloading, and data collection etc.

Background

Oil and gas can offer a number of challenges in IoT including Class 1 Division 2 requirements which aim to mitigate potential risks of fire and/or explosion, combined with remote locations. Making sure everything is in good working order can be a major challenge, which is why the move to remote monitoring and remote industrial automation is even more so during these new, challenging times. Faults must be detected as soon as possible, as downtime means not only revenue losses, but also costly labor.A remote monitoring system will help reduce maintenance costs, save labor, and more efficiently manage various machines on site, tracking the real time status of equipment, detect faults and enable preventive maintenance.

Solution

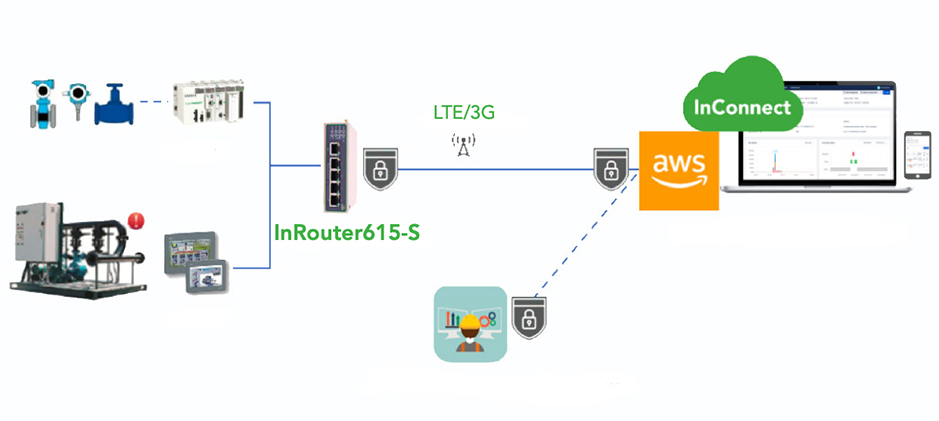

The InHand Networks IR615-S industrial LTE router and InConnect cloud service for remote access.

PLCs, HMIs and other smart devices around the well and compressor sites are connected to the IR615-S via Ethernet ports. Data collected from the now connected devices are then securely sent (encrypted) via OpenVPN, to the InConnect VPN platform via the LTE cellular networks, so that engineers can monitor these devices anytime from anywhere.

With secure remote connectivity, conduct online tests, variable tracking, maintenance and diagnostics, remote program uploading and downloading, data collection, etc become easy.

Advantages

- Reliable, secure and uninterrupted network access, available with LTE CAT6/4/1/M1, Wi-Fi and Ethernet

- Class I Division 2 certified, resilient in hazardous industrial environments

- 5 Ethernet ports, dual SIM, redundancy across carriers

- VPN tunnels protect data security

- FREE Device Manager for remote administration and management

- All industrial design, EMC grade 3, one of the widest operating temperature range in the industry (-20 ~ 70?)

- Cost-effective for networking

- Plug & play, no complex IT configurations required for remote connectivity

- Advanced security, better data protection

- Remote access without travel, greatly reduces time, labor and cost

- Preventive maintenance before problems arise, reducing downtime